Research and Development

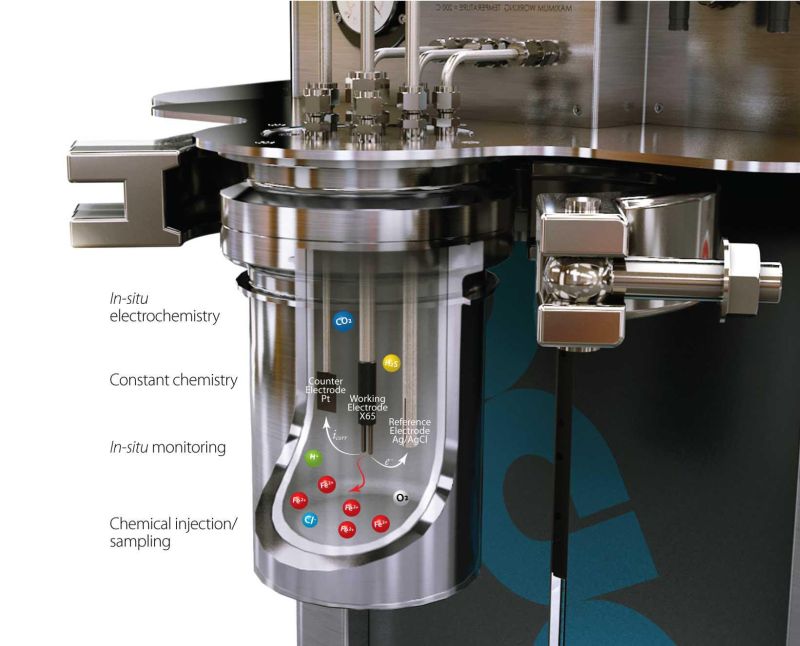

Our strategy for LBBC Baskerville is to reinvigorate the brand and align it with our Group vision by becoming a market leading supplier of small, high pressure, autoclave systems into niche global markets. Our early assessment of the market and discussions with the University of Leeds has identified a specific opportunity to develop an innovative range of high pressure autoclave systems incorporating continuous, real-time monitoring of the corrosion process being investigated within the vessel. This will be of great interest to the oil & gas industry for lab investigations of corrosion of materials exposed to high temperatures and pressures near the well-head and also to other sectors e.g. nuclear. The key to the success of any corrosion testing programme is that the conditions must match those seen in the field. The autoclave is a convenient means by which corrosion scientists can simulate oil and gas environments and replicate corrosion conditions. However, there are numerous existing shortcomings e.g. the conditions in the autoclave vary because the fluid is not continually replenished and the conditions are difficult to measure/monitor under extreme conditions.

IFS

The Institute of Functional Surfaces (iFS) at the University of Leeds, School of Mechanical Engineering is leading the field in translating the needs of industry into sensible and realistic testing programmes and therefore LBBC Baskerville will link up with the university through a Knowledge Transfer Partnership (KTP) programme. In this KTP, the expertise of the iFS group in corrosion evaluation, instrumentation of corrosion tests, advanced microscopy and supporting analysis is combined with the extensive autoclave manufacturing and control expertise existing in LBBC.

As oil wells get deeper and oil is found in increasingly extreme conditions then the equipment and testing protocols need to advance too. This programme will bring new knowledge to the product range which will stretch boundaries and advance the forefront of laboratory autoclave technology. Further development of autoclave technology, e.g. inclusion of sensing capabilities and creation of a dynamic product, depends on understanding the drivers in the field. The University of Leeds is recognised as a world leader in the area of corrosion testing and steady state monitoring and by working with LBBC who are recognised as a world leader in the design of pressure vessels and autoclave control systems it is felt that joint development of these innovative products will significantly enhance both our reputations whilst offering a range of innovative autoclave designs to simulate the harshest environments whilst having the ability to monitor sample and brine chemistry changes in situ.

Challenges in the field

In the Oil and Gas sector there are many challenges relating to cost-effective operational performance and asset integrity management. The ultimate goal for the industry is to maximise production with improved process safety. The presence of sand in production fluids and corrosive gases (in the aqueous phase), coupled with the shift towards deeper wells and the commercial pressures to increase production rates creates challenges for operators to maintain the integrity of piping and other process equipment. Another major consideration for the industry is safety. Many processes in the oil & gas and power generation industries are required to operate in extreme environments, often with high standards of safety and efficiency.

These environments vary and could be corrosive, abrasive or subject to extreme temperatures, pressures, vibration or contamination, or any combinations of these factors. Measurement technologies and systems that will enable accuracy, repeatability and reliability are vital to meet the growing challenges in these sectors. Current and future research is focused understanding the fundamentals in order to assist the industry in optimising product development for chemical companies, and to provide information for Oil and Gas operators to improve their asset integrity management strategies. Autoclave corrosion tests are a convenient means for laboratory simulation of many service environments. The reason for such tests is to recreate the high temperatures and high pressures commonly occurring in commercial or industrial processes. Downhole pressures can be up to 300 bar and temperatures can be 180 °C, or even higher in some fields.