Your corrosion testing partner

Our Story

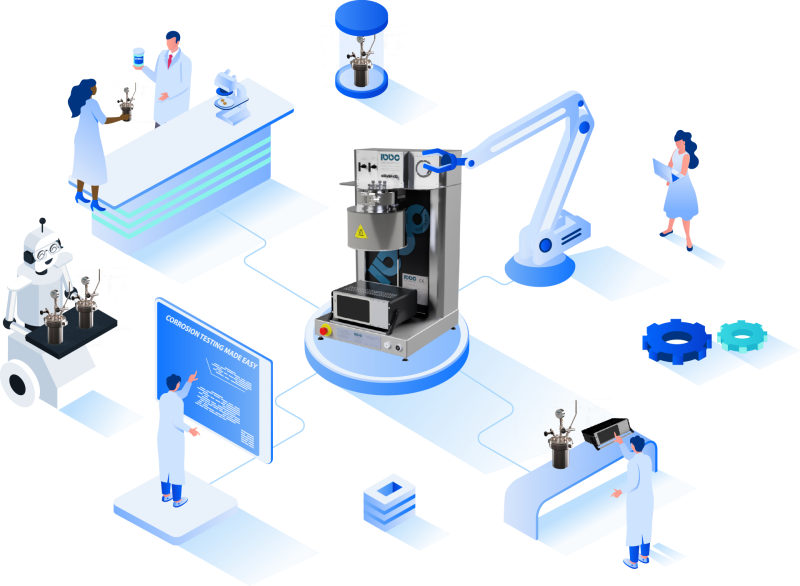

At LBBC Baskerville, we solve the biggest problems in autoclave corrosion testing: useability, safety, and the ability to simulate realistic corrosion mechanisms.

Inspired by the late Professor Anne Neville, OBE, LBBC Baskerville was formed in partnership with the University of Leeds and LBBC Group to combat the challenges that exist in autoclave technology used for corrosion testing.

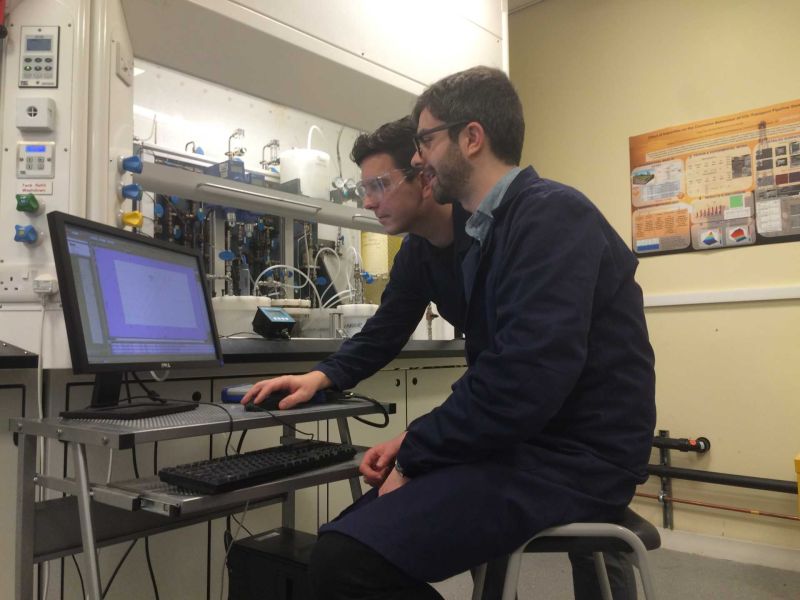

Dr Danny Burkle joined LBBC from the University of Leeds as a corrosion specialist and an experienced autoclave user. His frustrations in using autoclaves during his PhD, and his relationship with Anne, inspired Danny to embark on this journey with us to set new and improved standards for corrosion testing.

Our thinking is guided by the user; we want to improve the users experience of using an autoclave. Our autoclaves are designed to ensure ease of use, reliable data and the most important of all, a safe environment.

Next, our innovation is guided by the market; we look at the existing challenges in corrosion testing and target specific sector and corrosion problems to better simulate real environments and corrosion mechanisms.

Our Values

User Experience

Innovation

Build Trust

User Experience

Innovation

Build Trust

A Brief History of LBBC

Founded in 1876

The Leeds and Bradford Boiler Company was founded in 1876 to manufacture boilers and associated boilermaking for local crane suppliers, tar stills and brewing pans for local pubs.

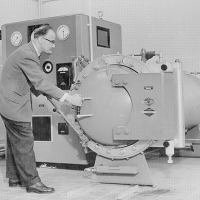

Invention of the Quicklock® door

Maurice Pickard gave the company a unique competitive advantage through his invention of the revolutionary Quicklock® door in 1934 which provided a very fast operating, reliable pressure containment door system, which is still used on LBBC products to this day.

The Group is formed

LBBC Baskerville is born

Our People

Our day to day projects and operations are supported by expert resource within LBBC Group.