Products

We offer a range of innovative solutions engineered for projects where pressure containment and temperature control are crucial. Our expertise helps us to deliver market leading solutions for material selection, chemical analysis and corrosion control and assessment applications.

Contact us today and we can help you achieve considerable savings in time and labour, with systems specified to suit the demanding conditions of your project.

Our Products

Manufactured in Leeds in the United Kingdom, our Autoclaves are simply pressure vessels that are specially designed and manufactured to run experiments at increased pressures and temperatures to help you improve your testing capabilities; whatever your required application.

Have a browse through our available products and call us or email us if you have any questions.

Pressure Vessels & Reactors

Model: PV & PR Models – Benchtop Standard Operating Range

Autoclave volume: 0.5 – 2.0 litre

Temperature range: -10 °C to +350 °C

Pressure range: atm to +134 bar

Standard Vessel/Cover Materials: 316Ti SS, C276

Standard Autoclaves

Model: SA Models – Standard Operating Range

Autoclave volume: 0.5 – 20.0 litre

Temperature range: -10 °C to +350 °C

Pressure range: atm to +134 bar

Standard Vessel/Cover Materials: 316Ti SS, C276

HPHT Autoclaves

Model: HPHT Models – High Pressure & High Temperature Operating Range

Autoclave volume: 0.5 –20.0 litre

Temperature range: -10 °C to +500 °C

Pressure range: atm to +250 bar

Standard Vessel/Cover Materials: 316Ti SS, C276

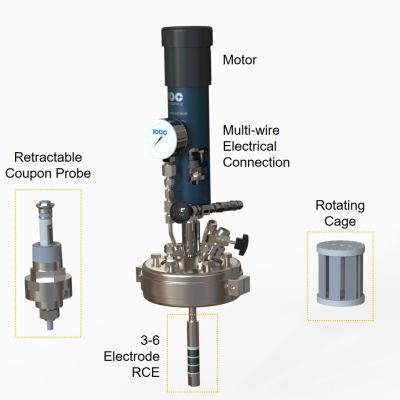

Corrosion Testing Autoclaves

Model: CTA Models – Corrosion Testing Range

Available Products*:

- Rotating Cage Autoclave

- 3-6 Coupon Rotating Cylinder Electrode (RCE) Autoclave

- Chemical Injection Autoclave

- Coupon Insertion/retraction Autoclave (Patented product)

*Specification suited to SA and HPHT Models based on your requirements.

Let us help you with your testing requirements to deliver problem-solving performance. Call us today.

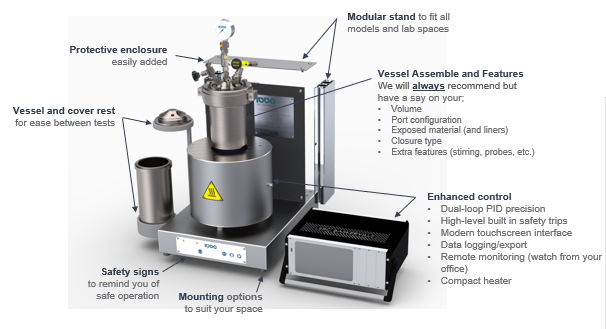

Flexibility in Design

The majority of our products are standard in size and dimensions and have been designed to be modular so you can easily interchange between different vessels using the same stand. We can customise the designs to suit you requirements if required, for example, if you need additional ports or vertical ports for electrochemistry/sensors, or bottom drain valves etc. We can also design new stands and arrangements to suit your exact available space if one of our standard stands doesn’t quite fit. If required, we can also assist in specifying your laboratory space and provide guidance on connections (such as exhaust, dump tanks etc) directing away from your autoclave.

Key Benefits

- Premium materials used throughout (Standard materials are 316Ti SS, C276/C22, 316SS + Tanatalum)

- All fittings in the vessel cover are Swaglok®

- Modern Appearance

- Designed for ease of use

- Modularity in design

- Easy operation split-clamp opening or one-bolt fast release clamp available for <250 °C

- Button operated lifting system for larger, heavy vessels

- Magnetic stirring coupling for absolutely leak tight stirring

- Customized configurations available

- Wide range of add-ons and additional features available

- Enhanced process control with advanced process data analysis using touch screen interface

- Compact electric heating (tuned for +/- 1 °C accuracy)

- Ongoing technical support throughout the product life

- Corrosion expertise and support

Safety Features

- Rupture disc installed to vessel which is mandatory

- Proportional relief valve installed (but can be removed if required)

- Over-temperature and pressure alarms and system shutdown if maximum working conditions are accidentally exceeded

- Software safety trips

- Hardware safety trips

- Emergency stop button available

- Admin and password protected different access levels

- All designs are independently reviewed by a third party inspection authority

- All designs have a healthy corrosion allowance built in to the vessel wall thickness

- Selected material will be suited to your application to minimise risk of corrosion

- Unable to open whilst pressurised

Typical Applications

- Corrosion Testing and Measurements

- Material Performance (Metal, alloys, composites and elastomers)

- Chemical Performance

- Inhibitor Performance

- Coating Breakdown and Performance

- Chemical research

- Nanoparticle synthesis

- Hydrogenation reactor

- Catalyst testing

- Crystallization

- Biomass research

- Biopolymer research