Our Future Products

At LBBC Baskerville, our vision is to provide products that will help to enhance corrosion control, prediction and management in order to improve on the safe and efficient recovery of hydrocarbons. With the ultimate goal of playing a role in preventing catastrophic corrosion related failures across the industry.

Working in partnership with the University of Leeds, specifically a team of corrosion experts lead by Professor Anne Neville; LBBC Baskerville are continuously developing new products that can help replicate field conditions realistically with the aim of improving corrosion testing, repeatability and industry standards.

Future applications and products will include:

- Severe service HPHT chemically inert autoclave with electrochemistry

- HPHT autoclave with electrochemistry in dynamic conditions in the presence of H2S

- Fully automated system with in-line inhibitor injection, brine sampling and the ability to monitor the brine chemistry for the duration of the test (O2 monitoring, pH monitoring, Fe2+ concentration monitoring)

- Coupon/electrode retractable system to remove/insert coupons periodically to eliminate pre/post-test corrosion and to analyse corrosion mechanisms over time without performing multiple tests

- Constant chemistry autoclave system featuring all of above

Advanced autoclave systems to incorporate:

- Dynamic loading machine (stress corrosion cracking)

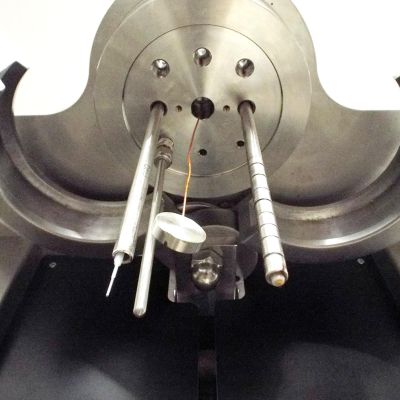

- In-situ tribometer (tribo-corrosion)

- In-situ jet impingement (Erosion-corrosion)

- Flow loop (Flow-induced corrosion)

- XRD/Raman Flow cells (In-situ corrosion product formation)

Linking Laboratory Corrosion Testing to Field Applications

Realistic Field Conditions

Extreme Environments

- Pressure and temperature conditions

- Highly corrosive (CO2/H2S, HC1, Acetic Acid)

Corrosive Fluid Chemistry, Properties & Variance:

- Constant chemistry (pH, Fe2+, SR)

- Accurate CO2/H2S partial pressures

- O2 concentration (<50 ppb)

- Seawater composition (% water cut)

- Presence of sand

- Inhibitor dosing

Properties / Condition of Corroding Surface:

- Corrosion rate and mechanisms

- Corrosion product formation

- Properties of the surface

- Exposure times

Simulating Flow Regimes / Hydrodynamics:

- Stagnant areas (bottom and top of the line)

- Reynolds Number (laminar/turbulent flow)

- Wall shear stress

Improving Testing Methods & Equipment

Advanced CRAs and Liners:

C276, Tantalum, PTFE, glass lined

Controlling chemistry:

Online monitoring, filtration system, injection / dosing system, larger dual autoclave

Sampling system:

Solution analysis

In-situ sensors:

pH, O2 content, working / counter / reference electrodes

Coupon configurations:

Weight loss, working electrode, micro / multiple

electrodes, crevice formers, stressed coupons, dynamic loading, in-situ tribometer, retractable coupons / electrodes, Devanathan cell

Real-time Corrosion Product Analysis:

Flow cell for in-situ XRD, window for digital

image correlation

Control of exposure time:

Retractable / insertable coupon / electrode system, dual autoclave, internal flow gasket

Controlled Flow:

Rotating cylinder / disk electrode, flow loop, in-situ jet impingement

Corrosion Mechanisms Simulated

CO2 Corrosion

- General corrosion

- Localised corrosion (pitting, crevice

corrosion) - Corrosion product formation:

FeCO3, Fe3O4, Fe2(OH2)CO3

H2S Corrosion

- Stress corrosion cracking

- Sulfide stress corrosion cracking

- Localised corrosion (pitting, crevice

corrosion) - Hydrogen permeation

- Corrosion product formation: FeS

Preferential Weld Corrosion

- Localised corrosion (pitting, crevice

corrosion) - Intergranular corrosion

- Galvanic corrosion